Chromium oxide green used as coloring

FDA Approved Green Pigments.

Used in paints and coatings

The extremely low oil absorption of DELIKECOLORS® chromium oxide green pigments results in a significantly higher pigment load, so that coatings using DELIKECOLORS® chromium oxide green pigments can be used with considerably improved hiding power compared to organic pigments. Chromium oxide pigments are therefore often used in combination with

organic pigments in high-gloss color coatings.

Thanks to their excellent sunlight resistance and their resistance to temperature, chemicals (including acids and alkalis) and weathering, they are also particularly suitable for coatings that must meet high durability standards. These include powder coatings and continuous coil coatings, baked enamels。

Chromium oxide pigments of submicron size (ultrafine powder), which are unique to DELIKECOLORS®, offer better dispersibility and a better reddish-green color, which can be achieved with very pure colors by simple shear dispersion.

Our chromium oxide green pigments are also compatible with most resins and additives and have a very beneficial stability.

Our chromium oxide green pigments last for decades without fading and can withstand the harshest weather elements or harsh environments!

We have the same shade of chromium oxide green as LANXESS-Bayferrox GN, GN-M, GX, GS, and have the same coloring effect. We also have chromium oxide green products with the same color tone as ELEMENTIS 4099, 8599, 6099.

This allows our Chromium Oxide Green products to be better incorporated into your formulations.

Cosmetics / Drugs:

FDA Drugs - Approved for use as a coloring agent indrugs for external use only in an amendment to the Food and Drug Regulations, Schedule No. 846, Department of National Health and Welfare, March 11, 1995.

Food Contact:

21CFR 178.3297 - Approved for use as a colorant in all polymers intended to contact food, at a level not to exceed 5% by weight. Listed under 21CFR 178.3297.

Resolution:

AP(89)1 - Council of Europe AP(89)1 Approved Pigments - migration of the elements antimony, arsenic, barium, cadmium, chromium, lead, mercury, and selenium from the following pigments are typically below the limits set forth in the Council of Europe resolution AP(89)1 on the use of colourants in plastic materials coming into contact with food, 13 September 1989.

AS2070-1999 - Australian Standard AS 2070-1999 Approved Pigments - migration of the elements antimony, arsenic, barium, cadmium, chromium, lead, mercury, and selenium from the following pigments are typically below the limits set forth in the Australian Standard AS 2070-1999, Plastics materials for food contact use (4.1.2 Colourants), published 5 March, 1999.

BfR IX - List of the BfR Approved Pigments: Pigments are not regulated by the Bundesinstitut für Risikobewertung (BfR) unless they contain dangerous substances.

FCN-Approved for use as a colorant in all polymers intended to contact food.Listed under FCN 1839.

GB9685 : 2016 - Pigments typically meet the purity requirements set forth in the National Food Safety of the People’s Republic of China, GB9685-2016 Standard for Uses of Additives in Food Contact Materials and Articles. Please see GB9685:2016 document for limitations.

Recycling:

CONEG - The following pigments, when used at a 25% maximum, typically contain a sum total of the regulated metals lead, cadmium, mercury, and hexavalent chromium below the strictest specification of 100 ppm set forth in the Model Toxics in Packaging (CONEG) legislation.

94/62/EC - The following pigments, when used at a 50% maximum, typically contain a sum total of the regulated metals lead, cadmium, mercury, and hexavalent chromium below the strictest specification of 100 ppm set forth in the Council of Europe Directive 94/62/EC, on packaging and packaging waste.

RoHS - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of hazardous substances in electrical and electronic equipment (RoHS).

ELV - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of Life Vehicles (ELV).

WEEE - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of Waste electronic and Electrical Equipment (WEEE) as they are currently written.

Toy Safety:

EN 71-3:2019+A1:2021 - The European Committee for Standardisation (CEN) has introduced an Element Migration Class Act for child contact products. Some of our chromium oxide green can meet this standard.

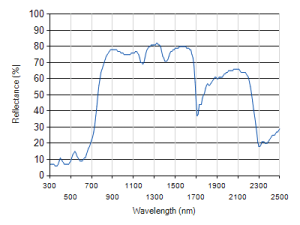

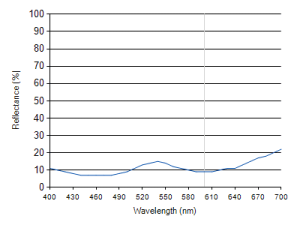

Imaging spectroscopy can obtain the spectral characteristics of a target while imaging it, and can be used for military reconnaissance to identify the difference between the spectral characteristics of a military target and the background environment. In other words, this technology makes the spectral signal different from the environmental background of the military target is completely exposed to its field of vision. In today's information war background, to be found means to be destroyed, imaging spectroscopy technology makes the military target's survivability is seriously threatened. In order to cope with this threat, military targets need to be close to the background environment in the wavelength range to be detected "the same colour and the same spectrum", that is, not only has a similar colour, but also has similar spectral characteristics. Usually, military targets on the ground mainly use green vegetation as the camouflage background, so it is of great significance to find and study bionic materials that can simulate the spectral characteristics of green vegetation and apply them to military camouflage to enhance the survivability of military targets.

So far, through the unremitting efforts of researchers, the existing high-performance camouflage coatings and devices in terms of colour, pattern, brightness and other aspects can be achieved with the green vegetation background fusion and matching, basically eliminating the military target in the visible wavelength band of the colour and outline characteristics, and basically achieved in a certain wavelength range and the approximation of the spectral characteristics of the green vegetation, which can be effective in deceiving the conventional imaging reconnaissance, but in the visible near-infrared region (visible) and the green vegetation (visible) and the green vegetation (visible) and the green vegetation. However, its fine reflectance spectrum in the visible near-infrared region (400~2,500 nm) still differs greatly from that of green vegetation.

Chromium trioxide Cr2O3, also known as chromium oxide or chromium green (Pigment Green 17, PG17), is available in two crystal types, α-Cr2O3 and γ-Cr2O3, of which α-Cr2O3 is the thermodynamically stable crystal type. α -Cr2O3 is corundum structure, belongs to the hexagonal crystal system, O2- in the crystal lattice is hexagonal dense accumulation, Cr3+ in these hexagonal dense accumulation of octahedral gaps, forming six-coordinated [CrO6]2-, similar to the octahedral field. Due to the overall electroneutrality of the crystal, only 2/3 of all octahedra are occupied by Cr3+. The visible near-infrared spectral reflectance properties of chromium oxide are mainly affected by the electronic orbital energy levels of Cr3+. The electron arrangement of Cr3+ is [Ar]3d3. Ideally, the five d-orbitals in free Cr3+ are merged without taking into account the ligand field effect and d-electron interactions. In fact, due to the mutual exclusion of electrons, the three electrons in the d-orbitals have different energy levels (different spectral terms), and the base spectral term 4F can be obtained for the d3 group state according to the Hund's rule and Pauli's principle. Moreover, the base spectral term splits further in the presence of the ligand field. In the octahedral field, the F term can be split into three spectral terms with different energies, 4A2g, 4T1g, and 4T2g. There are two transitions between the quadruple states of chromium oxide: 4A2g→ 4T2g and 4A2g→ 4T1g, which correspond to the two absorption bands in the UV-visible absorption spectrum of chromium oxide at 430~500 and 580~670 nm, respectively. It is because these two groups of jump absorption bands and chlorophyll porphyrin ring two groups of molecular orbital jump absorption bands in the same location, absorbing the energy of the visible region of the blue light and red light, but almost no absorption of the wavelength region of the green light, resulting in the formation of chromium oxide reflectance spectral curve around 535 nm corresponding to the reflectance peaks, close to the "green peak" position of the green vegetation. " position near the green vegetation.

Used in the manufacture of ceramic glass pigments

Cr3+ is an ion with 3d3 electron arrangement, which has the strongest six-coordination selectivity among all cations,so it not enters the four-coordination position.

Many ceramic pigments contain Cr2O3 as an important component, such as pink of Zn-Al-Cr series, brown of Zn-Al-Cr-Fe series, black of Co-Ni-Cr-Fe series, peacock green of Co-Zn-Al-Cr series, and green of Ca-Cr-Si series and Cr-Al-Si series. No matter which pigment is used, chromium is dissolved in the state of Cr3+.

Cr3+ is a very stable cation in glaze, especially when it is used in the color of spinel series, the content of Cr2O3 is closely related to the stability of glaze. In the spinel structure, six coordination sites are connected vertically and horizontally by the common edges that constitute regular octahedron, forming a spinel skeleton. If this skeleton

structure is successfully maintained in glaze, the color of spinel series will be very stable. Cr3+ with the strongest six coordination selectivity should occupy these six coordination sites preferentially. With the increase of Cr3+ occupation, the structure of spinel is more complete, which strengthens the stability of glaze. Among Co[Cr2]O4, CoO-Cr2O3 (malachite green) is the color with the most Cr2O3, and the 6 coordination sites are completely occupied by Cr3+, which ensures its stability to various glazes

The chromium oxide green pigments suitable for black in DELIKECHEM® are all high-temperature chromium oxide green, and the color development effect of chromium oxide green in black can be improved by increasing the conversion temperature of chromium oxide green.

Compared with the traditional chromium oxide green,DELIKECHEM® special chromium oxide green for cobalt black can improve Delta L*≈-1.0~-2.0.

Compared with the traditional chromium oxide green,DELIKECHEM® red-brown special chromium oxide green can get a darker, redder and bluer red-brown color. The special chromium oxide for golden brown can make the calcined golden brown more bright yellow.

Compared with the traditional chromium oxide green,DELIKECHEM® blue-specific chromium oxide green can get a darker and bluer blue. In the same formula, the Delta b* value of cobalt chromium blue pigment made by our chromium oxide green pigment is 2 ~ 3 blue than that produced by cobalt chromium blue pigment made by traditional chromium oxide green pigment.

Used in Concrete / Asphalt / Flooring

DELIKECHEM® synthetic chromium oxide pigments exhibit nearnatural green in concrete and other gel materials, which is not only gorgeous but also lasting.

Our synthetic chromium oxide pigments meet ASTM C979 requirements, not only light-resistant, non-migration and antialkali resistance. Our synthetic chromium oxide pigments are very dispersing, and their small particle size makes it easy to achieve

the ideal dispersion effect when mixed with concrete, which can make decorative concrete have a consistent and uniform coloring appearance.

When using our synthetic chromium oxide pigment in standard dosage, the strength and workability of concrete will not be affected, and the surface temperature of concrete will be greatly reduced because of its unique near infrared reflectivity, which will significantly prolong the service life of concrete.

Grey concrete is mostly used in most buildings, but the coloring of gray concrete will reduce the brightness of pigment in cement, which makes colored concrete not beautiful enough. Therefore, we often suggest customers to realize the coloring effect of colored concrete in white concrete.

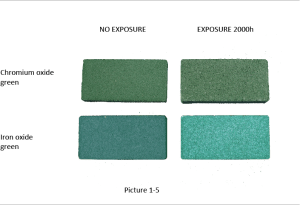

Iron oxide green is a mixture of iron oxide yellow and phthalocyanine green. Because of its mobility and light resistance, it is not within the requirements of ASTM C979 and BS EN 12878. However, it is often used because of its low price, but it cannot achieve the effect of synthesizing chromium oxide green pigment in use.

We exposed iron oxide green and chromium oxide green pigment in Dunhuang for 2000 hours, and obtained the results as shown in Figure 1-5

We analyze the influence of chromium oxide green pigment, iron oxide red, iron oxide green and phthalocyanine green pigment on concrete strength, and draw a conclusion

that synthetic iron oxide green and phthalocyanine green are unstable and have poor durability, and the compressive strength of concrete decreases continuously with the increase of the addition amount. On the other hand, chromium oxide green pigment and iron oxide red pigment will improve the compressive strength of concrete as long as the

addition amount of pigment is controlled within 6%We analyze the influence of chromium oxide green pigment, iron oxide red, iron oxide green and phthalocyanine green pigment on concrete strength, and draw a conclusion that synthetic iron oxide green and phthalocyanine green are unstable and have poor durability, and the compressive strength of concrete decreases continuously with the increase of the addition amount. On the other hand, chromium oxide green pigment and iron oxide red pigment will improve the compressive strength of concrete as long as the addition amount of pigment is controlled within 6%

Colored concrete may be weathered after long-term exposure to natural environment, especially under the action of climate change, ultraviolet radiation and chemical erosion. Weathering refers to the phenomenon that the color of concrete surface changes, fades or loses its original bright color.

This may be due to insufficient photostability of pigments or poor adhesion between pigments and concrete substrates.

In order to reduce the weathering degree of colored concrete, the following measures can be considered:

Choose pigments with good weatherability: Choose pigments with good weatherability, such as pigments after stable treatment, to keep the color bright and lasting.

Optimizing concrete mix ratio: Appropriate water-binder ratio, additives and admixtures are adopted to improve the durability and weathering resistance of concrete.

Surface protective coating: A transparent protective coating, such as polymer coating or varnish, is applied to the surface of colored concrete to increase color stability and provide additional protection.

Regular maintenance and cleaning: Regular maintenance and cleaning of concrete surface to prevent the accumulation of dust, dirt and chemicals, which helps to prolong the service life of colored concrete.

Plastic Colouring Use

Chromium Oxide Green is compatible with most resins and can meet the requirements of most injection, extrusion and blow molding processes.

Chromium oxide green has good light and heat resistance in plastics. It can maintain the color stability of plastic products under sunlight irradiation and is not easy to fade and change color. At the same time, it is also able to withstand a certain high temperature and maintain the stability and brightness of the color.

Chromium oxide green has good stability and resistance to general chemical substances. It is able to withstand certain acidic and alkaline environments without significant changes and fading. This allows Chromium Oxide Green to be applied to plastic products in a variety of chemical environments.

Chromium Oxide Green has good color dispersion in plastics and can be evenly dispersed in the plastic matrix. This allows the pigment to give full play to its color effect, giving the entire plastic product a uniform green color.

Cosmetics / Drugs:

FDA Drugs - Approved for use as a coloring agent indrugs for external use only in an amendment to the Food and Drug Regulations, Schedule No. 846, Department of National Health and Welfare, March 11, 1995.

Food Contact:

21CFR 178.3297 - Approved for use as a colorant in all polymers intended to contact food, at a level not to exceed 5% by weight. Listed under 21CFR 178.3297.

Resolution:

AP(89)1 - Council of Europe AP(89)1 Approved Pigments - migration of the elements antimony, arsenic, barium, cadmium, chromium, lead, mercury, and selenium from the following pigments are typically below the limits set forth in the Council of Europe resolution AP(89)1 on the use of colourants in plastic materials coming into contact with food, 13 September 1989.

AS2070-1999 - Australian Standard AS 2070-1999 Approved Pigments - migration of the elements antimony, arsenic, barium, cadmium, chromium, lead, mercury, and selenium from the following pigments are typically below the limits set forth in the Australian Standard AS 2070-1999, Plastics materials for food contact use (4.1.2 Colourants), published 5 March, 1999.

BfR IX - List of the BfR Approved Pigments: Pigments are not regulated by the Bundesinstitut für Risikobewertung (BfR) unless they contain dangerous substances.

FCN-Approved for use as a colorant in all polymers intended to contact food.Listed under FCN 1839.

GB9685 : 2016 - Pigments typically meet the purity requirements set forth in the National Food Safety of the People’s Republic of China, GB9685-2016 Standard for Uses of Additives in Food Contact Materials and Articles. Please see GB9685:2016 document for limitations.

Recycling:

CONEG - The following pigments, when used at a 25% maximum, typically contain a sum total of the regulated metals lead, cadmium, mercury, and hexavalent chromium below the strictest specification of 100 ppm set forth in the Model Toxics in Packaging (CONEG) legislation.

94/62/EC - The following pigments, when used at a 50% maximum, typically contain a sum total of the regulated metals lead, cadmium, mercury, and hexavalent chromium below the strictest specification of 100 ppm set forth in the Council of Europe Directive 94/62/EC, on packaging and packaging waste.

RoHS - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of hazardous substances in electrical and electronic equipment (RoHS).

ELV - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of Life Vehicles (ELV).

WEEE - The following pigments meet the purity thresholds for lead, cadmium, mercury and hexavalent chromium as specified in European Directives for the End of Restrictions on the use of Waste electronic and Electrical Equipment (WEEE) as they are currently written.

Toy Safety:

EN 71-3:2019+A1:2021 - The European Committee for Standardisation (CEN) has introduced an Element Migration Class Act for child contact products. Some of our chromium oxide green can meet this standard.

Kevin Shi

Vice General Manager

Sales and purchasing Responsible for the Chromium Oxide Green project

SITE DESIGN BY: DELIKETECH

- General Terms and Conditions of Sale

- Code of Business Conduct